When it comes to industrial machinery or even basic home appliances, a pressure switch plays an essential role. One such pressure switch that stands out in various applications is the 0533205 pressure switch. Whether you’re a DIY enthusiast or a professional in the field, understanding how this component works can make all the difference in ensuring your systems run smoothly. In this blog post, we’ll dive deep into what the 0533205 pressure switch is, how it functions, where it’s commonly used, and why it could be the right choice for your project. So, let’s break it down in a way that anyone can understand.

What is a Pressure Switch?

A pressure switch is a critical component used to monitor and regulate pressure within various systems. It functions by controlling electrical circuits based on specific pressure thresholds. This device plays a crucial role in safeguarding equipment from potential damage and ensuring the efficient operation of systems across diverse applications, including HVAC systems, water pumps, and industrial machinery.

How Does the 0533205 Pressure Switch Work?

The 0533205 pressure switch operates based on pressure sensitivity. Here’s a simple breakdown of how it works:

Pressure Monitoring: The switch is connected to a system where it continuously monitors the pressure.

Activation Point: When the system’s pressure hits a certain threshold (either too high or too low), the switch is triggered.

Electrical Signal: Once triggered, the switch either opens or closes the circuit, controlling the flow of electricity.

System Adjustment: This, in turn, adjusts the machinery or appliance it’s connected to—like shutting off an air compressor if pressure gets too high.

Why Do You Need a Pressure Switch?

Pressure switches, including the 0533205 model, are vital for any system where pressure needs to be maintained within specific limits. Whether it’s to prevent damage to equipment, avoid safety risks, or ensure that processes like filling tanks, controlling compressors, or managing heating systems run properly, the switch steps in to either stop or start an action when the pressure level hits a certain point.

For example, in an air compressor, the pressure switch can cut off the power when the air tank is full, preventing it from over-pressurizing. It turns the system back on when the pressure drops too low, keeping the operation efficient and safe.

Read Next: 89.7 86.01 82 95

Key Features of the 0533205 Pressure Switch

The 0533205 pressure switch offers a range of features that make it suitable for many industrial and commercial applications:

High precision: It responds quickly and accurately to changes in pressure.

Durability: Built to withstand tough environments, the switch is designed for long-term use, making it a reliable choice for heavy-duty applications.

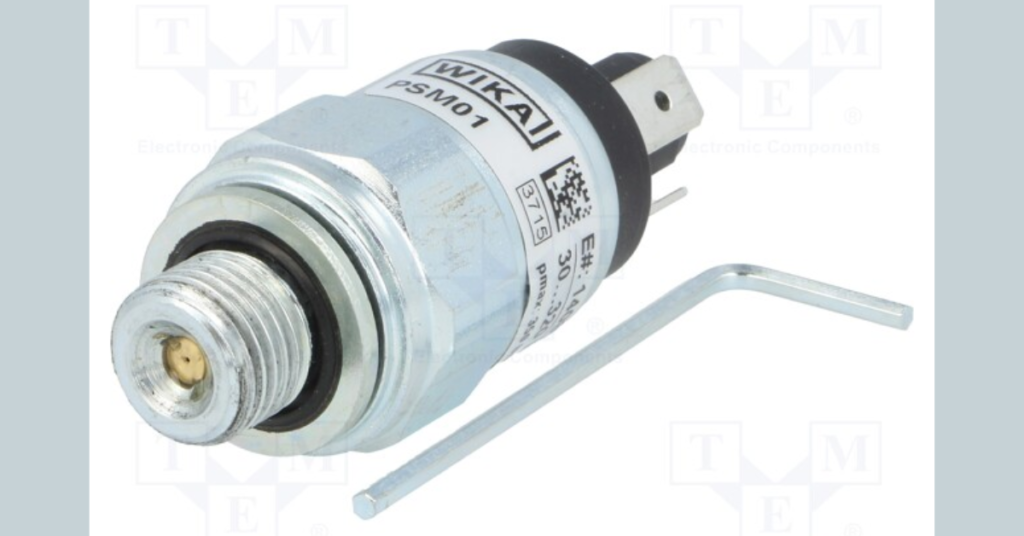

design compact: It doesn’t take up too much space in your system, which is ideal if you’re working with limited room.

Versatility: The switch can work with a range of different pressures, depending on the specific system you’re using.

These features make the 0533205 pressure switch a reliable and cost-effective solution for managing pressure in your operations.

Common Applications of the 0533205 Pressure Switch

This pressure switch is incredibly versatile and can be used in a variety of applications. Here are a few common examples where you might find the 0533205 pressure switch at work:

HVAC systems: Heating, ventilation, and air conditioning units often rely on pressure switches to ensure proper airflow and maintain system integrity.

Air compressors: As mentioned earlier, pressure switches in air compressors keep the system running safely by cutting power when the pressure gets too high and restoring it when the pressure drops too low.

Pumping systems: The switch regulates the pressure in water or oil pumps, ensuring that the fluid is delivered at a consistent rate without overworking the pump.

Safety systems: In systems where pressure management is essential for preventing accidents or equipment failure, the switch acts as a safeguard, shutting down the system before dangerous levels are reached.

Maintenance Recommendations

Routine Inspections: Carry out regular inspections of the switch to detect any wear, damage, or corrosion. Address any issues immediately to avoid system failures.

Keep Pressure Ports Clean: Maintain the cleanliness of the pressure ports to ensure accurate readings. Use compressed air or a soft brush to remove any dirt or debris.

Functional Testing: Periodically test the switch to confirm proper operation. Simulate different pressure levels using a calibrated source to check how the switch responds under varying conditions.

By following these installation and maintenance practices, the 0533205 pressure switch will provide optimal performance and a longer operational lifespan, helping to prevent costly repairs or system failures.

FACTS

- Purpose: The 0533205 pressure switch is designed to monitor pressure levels in various industrial and mechanical systems, activating or deactivating circuits based on set pressure thresholds.

- Applications: Commonly used in HVAC systems, compressors, hydraulic and pneumatic systems, and process control equipment.

- Durability: It is built to withstand harsh environments, including exposure to varying temperatures, moisture, and dust, making it suitable for industrial settings.

- Accuracy: The switch provides precise pressure monitoring, ensuring system stability and preventing damage from over- or under-pressurization.

- Installation: The 0533205 pressure switch features easy installation with adaptable mounting options, making it compatible with a variety of systems.

- Maintenance: Regular inspections, cleaning of pressure ports, and functional testing are necessary to maintain optimal performance and extend the switch’s operational life.

- Material: Typically constructed from corrosion-resistant materials to ensure longevity even in corrosive or high-moisture environments.

FAQs

What is the function of the 0533205 pressure switch?

The 0533205 pressure switch monitors pressure levels within a system and activates or deactivates circuits when the pressure reaches pre-set thresholds, ensuring system safety and efficiency.

Where is the 0533205 pressure switch commonly used?

It is commonly used in HVAC systems, hydraulic and pneumatic systems, compressors, and other industrial applications where pressure regulation is crucial.

How often should I perform maintenance on the pressure switch?

Regular maintenance, including inspections, cleaning of pressure ports, and functional testing, should be done periodically, depending on the environment and the application. A good rule of thumb is to inspect and test the switch every 3 to 6 months.

How do I clean the pressure ports?

To clean the pressure ports, use compressed air or a soft brush to remove dirt, debris, or any blockages. Ensure the ports are clear for accurate pressure readings.

Can I adjust the pressure settings on the 0533205 pressure switch?

Yes, most 0533205 pressure switches have adjustable pressure set points, allowing you to tailor the switch’s activation and deactivation thresholds based on system requirements.

Conclusion

The 0533205 pressure switch is a critical component in various industrial and mechanical systems, providing precise pressure monitoring to maintain system efficiency and safety. Regular inspections, cleaning, and functional testing are essential to ensure its optimal performance and longevity. By following proper maintenance practices, such as keeping pressure ports clean and conducting routine functional tests, users can avoid costly repairs and system failures. Overall, the 0533205 pressure switch offers durability, reliability, and customization options, making it a valuable asset for pressure regulation in demanding environments.

Stay Connected: Truenetworth.org